Steel Telecom Towers

From Steel to Signal: The Technology Behind Telecom Towers

In today’s hyper-connected world, telecom towers form the invisible backbone of global communication. From mobile phones and internet data to emergency response systems and smart city networks, these structures enable seamless connectivity that modern life depends on.

What Are Telecom Towers?

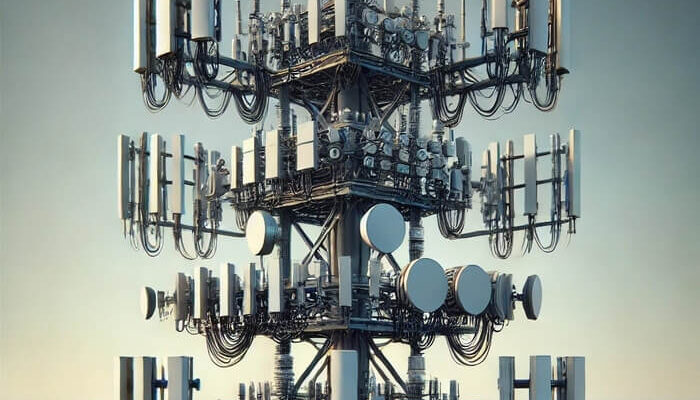

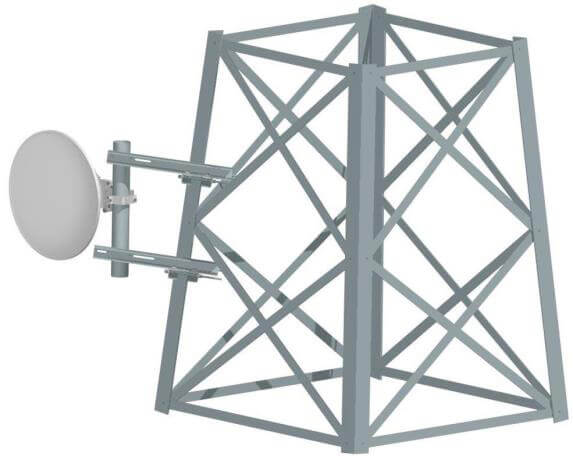

A telecom tower supports antennas, transmitters, and other communication devices that send and receive radio signals. Additionally, These structures create wireless coverage across cities, industrial areas, and rural regions.

Furthermore, Engineers build towers in different styles — lattice, monopole, guyed, or camouflaged — depending on site conditions and coverage requirements.

Types of Telecom Towers

-

Lattice Towers

Steel lattice towers offer excellent strength and wind resistance. Their open-frame design keeps the weight low while providing wide-area coverage — ideal for rural or industrial zones. -

Monopole Towers

Monopoles stand on a single steel column. They take up minimal space, install quickly, and require little maintenance. They are common in urban and roadside locations. -

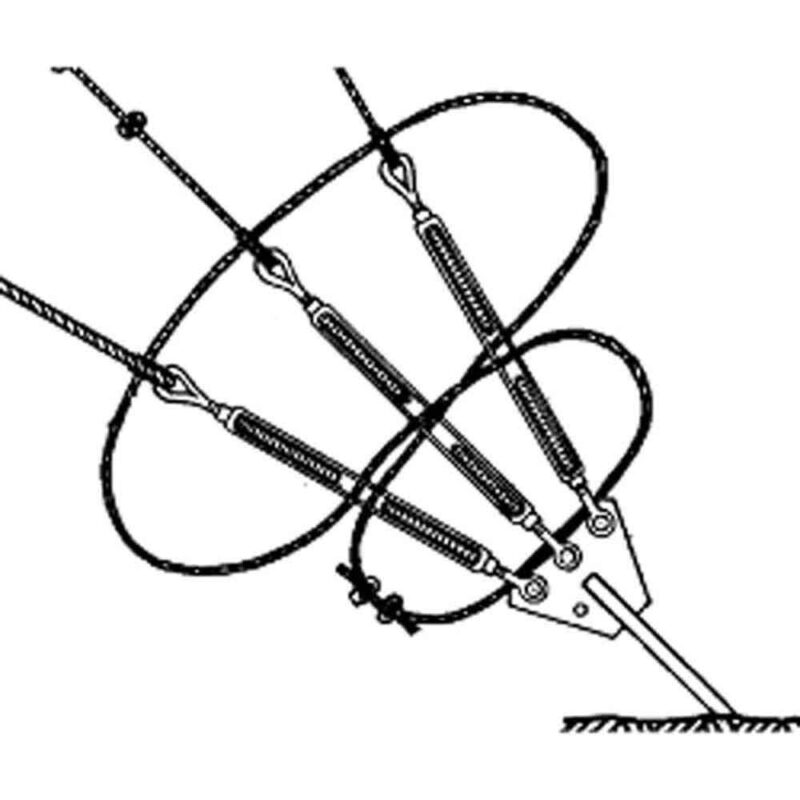

Guyed Towers

Guyed towers use steel cables for stability, allowing engineers to build them taller at a lower cost. They perform well in open environments such as plains or deserts. -

Camouflaged or Stealth Towers

In summary, These towers blend into surroundings by resembling trees, flagpoles, or light posts. They protect the visual landscape while maintaining strong network performance.

MTS tower modern tower solutions will give extra advantages for your projects. Please contact us to get more information.

Why Telecom Towers Matter

Every text, call, or data transfer relies on a nearby telecom tower. Towers lift antennas high above the ground, improving signal strength and reducing interference. They also expand coverage zones and increase network reliability.

As users stream more data and connect more devices, tower networks become even more critical for 5G and IoT communication. Without them, connectivity would weaken, and digital systems would slow down.

Innovation and Quality at MTS Tower

MTS Tower designs and manufactures self-supporting towers, monopoles, rooftop structures, and Cell on Wheels (COW) units for both permanent and mobile networks. The company delivers complete solutions — from concept to installation — helping telecom operators expand their coverage quickly and efficiently.

With operations across Europe, Canada, and the Middle East, MTS Tower builds every product according to international engineering standards. The company also holds ISO 10002 certification for customer satisfaction, proving its commitment to consistent quality.

Also, Each tower leaves the factory ready for easy assembly, reduced transport costs, and long service life. MTS Tower engineers customize every project to meet technical and budget requirements without compromising performance.

Furthermore, Sustainability remains a key focus. The company develops energy-efficient tower systems, integrates solar and hybrid power options, and uses recyclable materials to reduce environmental impact.

The Future of Telecom Infrastructure

As 5G expands worldwide, telecom networks need more flexible tower systems. Moreover, The market now demands small cell sites, rooftop installations, and modular mobile towers that can adapt to new technologies.

Cell on Wheels (COW) systems provide quick and temporary coverage during events, emergencies, or network upgrades. Furthermore, MTS Tower continues to lead this segment with innovative, modular designs that support fast deployment and reliable service.

MTS Steel Towers

Telecom towers connect communities, industries, and nations. Also, They form the foundation of global communication and digital growth.

MTS Tower continues to strengthen this foundation by producing high-performance, sustainable, and cost-effective telecom towers that support 4G, 5G, and future network generations. Through engineering excellence and global reach, MTS Tower builds the structures that keep the world connected — today and tomorrow.

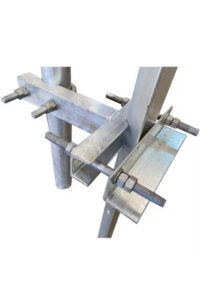

Superior Galvanization for Long-Term Durability

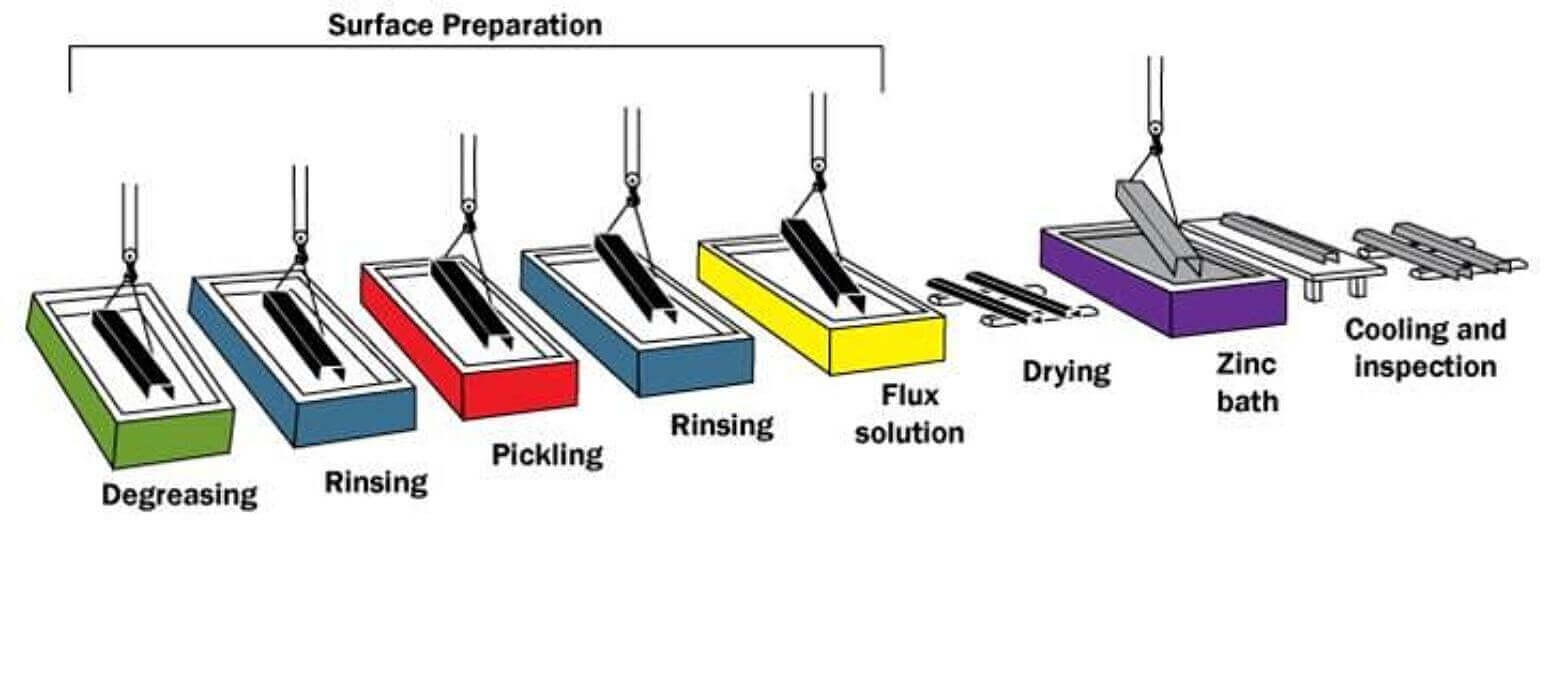

Corrosion protection is one of the most critical factors in the life cycle of a telecom tower. To ensure maximum longevity and reliability, all MTS Tower steel structures undergo hot-dip galvanization in accordance with the highest international standards.

Therefore, The galvanization process involves immersing fabricated steel components in molten zinc at around 450°C (840°F). This creates a metallurgically bonded zinc coating that shields the steel from rust, oxidation, and harsh weather conditions — even in coastal or high-humidity environments.

Also, MTS Tower follows the latest versions of ASTM A123 / A153, EN ISO 1461, and BS EN ISO 14713 standards for galvanization quality and coating thickness. Every batch is inspected and tested for zinc coating uniformity, adhesion, and minimum thickness compliance.

Thanks to its advanced facilities and strict quality control procedures, MTS Tower ensures:

-

Uniform coating thickness on all tower components

-

Superior corrosion resistance for more than 25 years of outdoor service life

-

Smooth surface finish that simplifies installation and improves aesthetics

-

Traceable galvanization certificates and test reports for each production lot

Moreover, This focus on galvanization quality gives MTS Tower customers a clear advantage — longer service life, lower maintenance costs, and greater reliability in extreme climates.